DS-DPD

Storage Methods : Storage to avoid direct sunlight, moisture in and keep packing condition;

Storage Period : Room temperature in ambient humidity, (23±10℃,55±15%RH)12 Months/12

Packaging :

- 200m X 9 Rolls

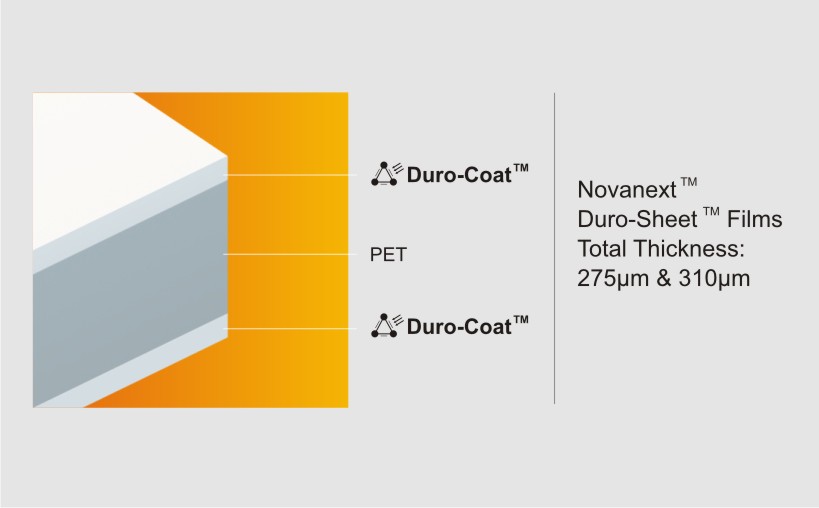

| Item | Units | Value | Standard | |

| Product Thickness | um | 275 ± 5% / 310 ± 5% | GB/T 13541-92 | |

| Tensile Strength(MD/TD) | MPa | MD ≥ 100、TD ≥ 100 | ISO 527.3 | |

| Elongation of Break(MD/TD) | % | MD ≥ 100、TD ≥ 100 | ISO 527.3 | |

| Heat sShrinkage (MD/TD) 150℃*30min | % | MD ≤ 1、TD ≤ 0.5 | IEC 62788-1-5 | |

| Peel Strength | N/cm | ≥ 5 | ISO 8510-2:2006 | |

| BS/EVA Peel Strength | N/cm | ≥ 70 | ISO 8510-2:2006 | |

| Inner layer Reflectivity | % | ≥ 80 | ISO 9050 : 2003 | |

| Sand Drop Resistance | L | ≥ 110 | ASTM D968 | |

| Water Vapour transmission 38℃ 90%RH (IR) | g.m2 /day | ≤ 1.8 | ISO15106-3 | |

| SI Cohesiveness | − | Well | 15Kg/3min | |

| Breakdown Voltage | KV |

≥ 20 | IEC 62788-2:2017 | |

| Partial Discharge | VDC | ≥ 1000 / ≥ 1500 | IEC 62788-2:2017 | |

| DH Test(1000H) | Yellow Index |

– | ≤ 2 | IEC 62788-2:2017 |

| Elongation of Break | % | ≥ 50 | IEC 62788-2:2017 | |

| UV Test(2000H) | Yellow Index |

– | ≤ 2 | IEC 62788-2:2017 |

| Elongation of Break | % | ≥ 50 | IEC 62788-2:2017 | |

| Thermocycling Test (200 Times) | Yellow Index |

– | ≤ 2 | IEC 62788-2:2017 |

| Elongation of Break | % | ≥ 50 | IEC 62788-2:2017 | |

| Humidity-Freeze Test (10 Times) | Yellow Index | – | ≤ 2 | IEC 62788-2:2017 |

| Elongation of break | % | ≥ 50 | IEC 62788-2:2017 | |

Prestigious Clients

Our Valuable Customers